Research Field Robotics and Assembly Technology

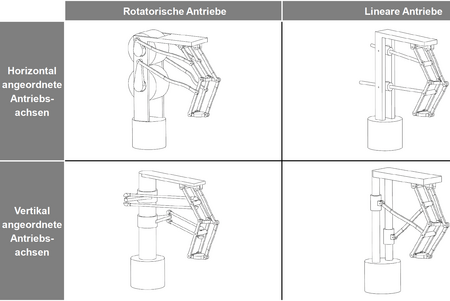

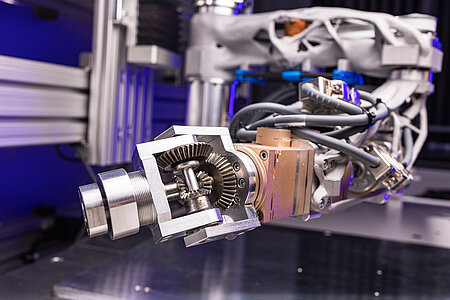

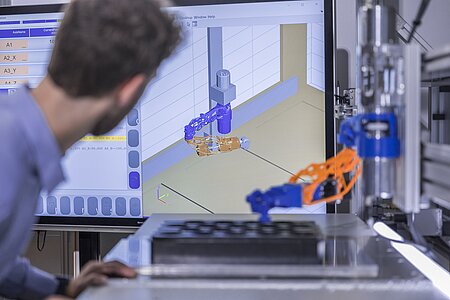

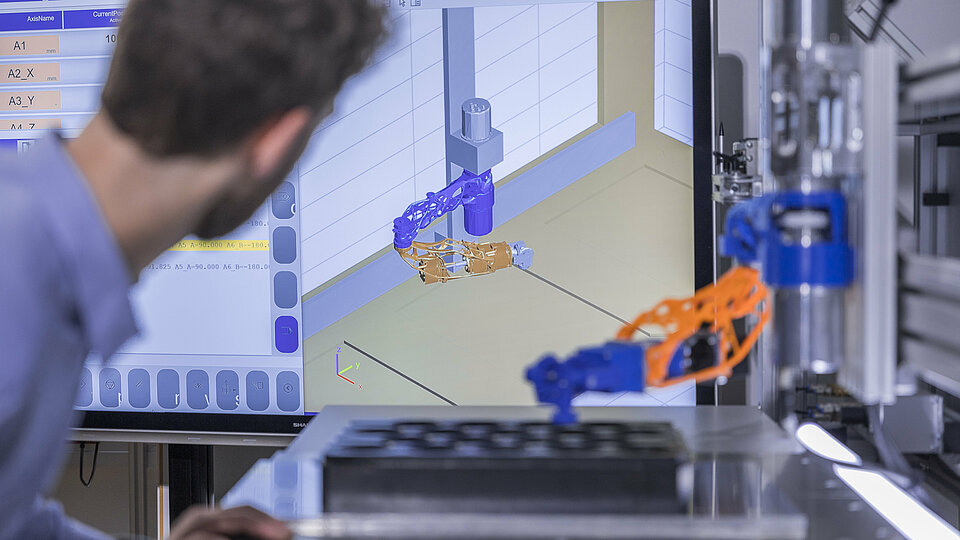

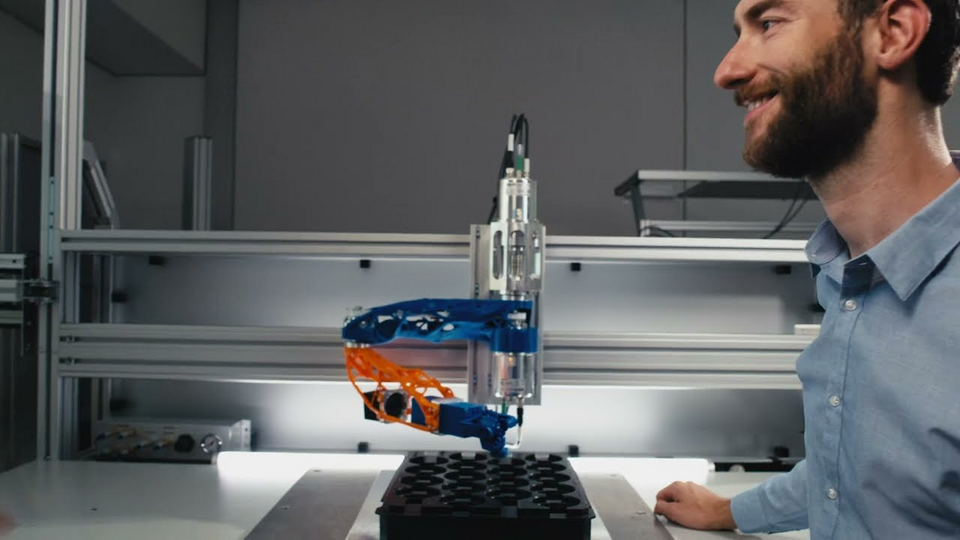

Kinematic structures and motion parameters are derived from the specific requirements of the assembly process, especially for precision engineering products. New solutions for mechanical structures, drives, joints or end-effectors are developed. The focus of our work is the overall system. Therefore, the development of the associated control system, including user-oriented programming functionalities, is part of the scope of our projects.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy .

Innovative automated assembly solutions

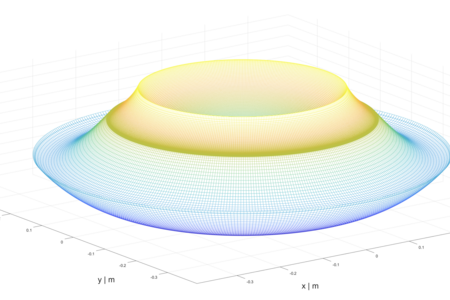

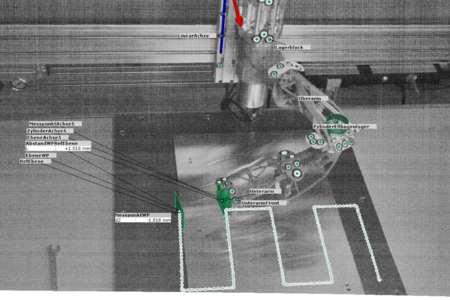

Modern methods for topology optimization enable the improvement of mechanical structures in terms of low component weight while maintaining high stiffness. The designs are realized by means of generative manufacturing processes in plastic or metal. Model-based multi-body simulations are used to elaborate the designs to determine kinematic parameters such as velocities or drive torques of individual axes. The novel assembly solutions are verified on practice-oriented prototypes. High-performance 3D measurement systems are available for this purpose.

Impressions