Mechanical Engineering

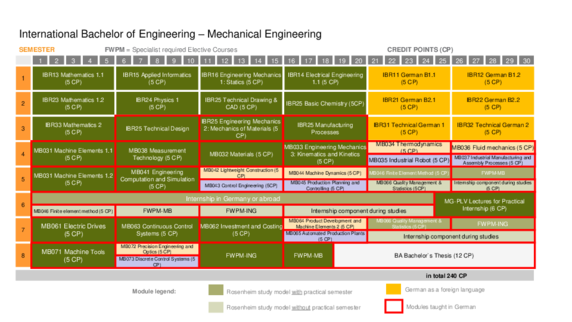

This programme is avalaible as a specialisation of the Bachelor's degree programme International Bachelor of Engineering.

Career Opportunities

As mechanical engineers work in almost all branches of industry, numerous areas of employment become accessible to Mechanical Engineering graduates – including, above all, those of planning, construction and production, environment management and energy management.

Learning Contents

Whether we are talking electronic devices, precision mechanical tools, automobiles or production plants – mechanical engineering is pivotal to nearly everything we produce in our modern industrial society. Mechanical engineers produce construction drawings, develop prototypes for machines and equipment, plan, manage and optimise production and by doing so sustain technical progress.

Module Handbook

Curriculum and Module Handbook for the IBE specialisation Mechanical Engineering.

Module Descriptions

FWPM modules

FWPM modules are specialist required elective courses offered during the later semesters. Students can choose from a portfolio of courses to personalise their engineering profile with interdisciplinary skills and gain specialist knowledge and methods of their discipline. A selection of courses is announced by the faculty in advance for each semester.

Semester 3

Semester 4

Semester 5

Semester 6

Semester 7

Semester 8

Take a Campus Tour!

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy .

Study International Bachelor of Engineering

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy .