Robotics and Assembly Technology

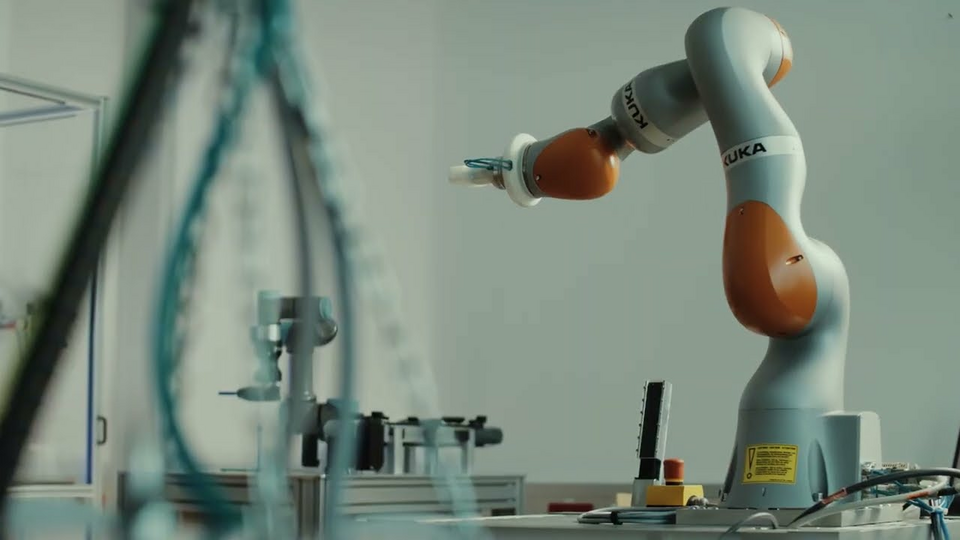

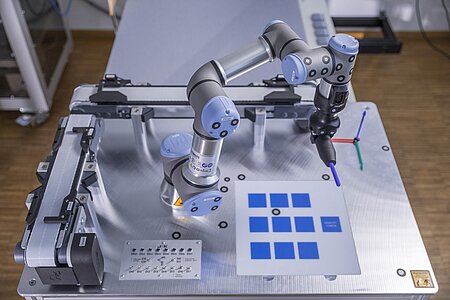

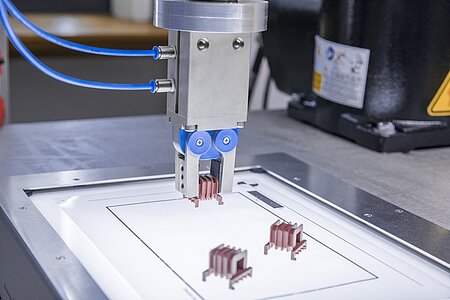

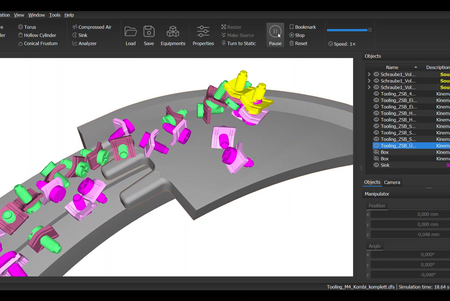

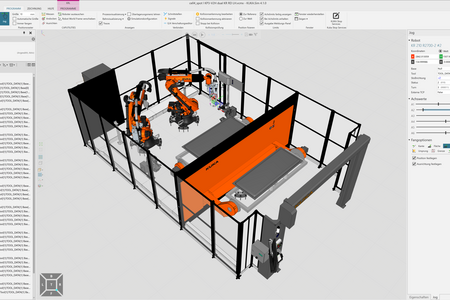

Automation technology is a prerequisite for economic success in industrial assembly. Industrial robots with different kinematic structures are essential elements. They are complemented by a selection of application-specific peripheral systems such as image recognition systems for planning motion sequences or grippers for handling the workpieces. The planning of assembly workstations is supported by powerful simulation systems.

Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy .

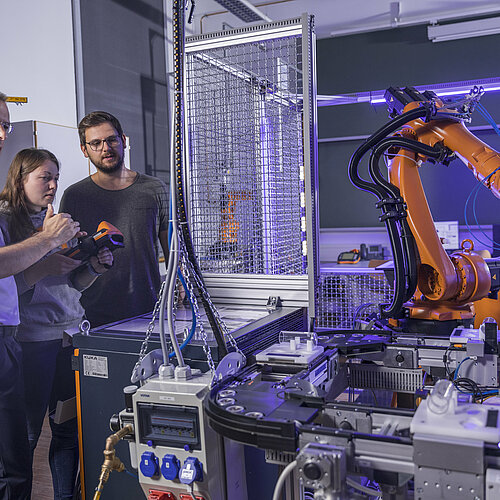

Interaction with robots

The courses “Industrial Robotics” and “Assembly technology” cover the fundamentals of robotics and assembly technology. The course contents are deepened on practical test benches with state-of-the-art industrial components. The 4- to 7-axis robots are coupled with different conveyor technology or image processing systems. Collaborative robotics is possible with integrated force and torque sensors. Focus in the Master courses are topics on technology and planning of assembly systems, such as 3D-human-simulation, hybrid assembly with robotic assistance and safety technology for automation.

Impressions from the lab

To the lab assembly automation and robotics